Essential Tips for Successful Welding Inspection Madison Services

Essential Tips for Successful Welding Inspection Madison Services

Blog Article

Exploring Advanced Equipment and Approaches for Accurate Welding Inspection

In the world of welding assessment, the search of precision and integrity is critical, stimulating the advancement of cutting-edge tools and methods. Technologies such as phased range ultrasonic screening and digital radiography are transforming issue discovery, supplying unrivaled accuracy in characterizing welding problems. Laser scanning innovations and automated assessment systems, outfitted with synthetic knowledge, are redefining the landscape by minimizing human error and enhancing safety and security steps. As these innovative techniques remain to evolve, they assure not just to transform inspection methods however likewise to increase interesting concerns regarding the future of high quality assurance in commercial applications.

Ultrasonic Examining Advancements

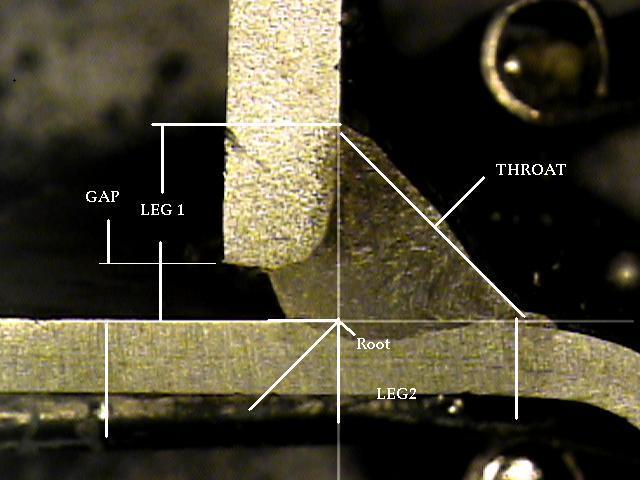

Ultrasonic screening developments often represent the forefront of developments in welding examination modern technologies. These developments have actually dramatically enhanced the ability to discover and examine gaps within bonded structures, ensuring boosted honesty and safety and security.

Additionally, innovations in software program formulas for information analysis have actually enhanced the precision of issue discovery and sizing. Automated ultrasonic screening systems currently use high-resolution imaging, making it possible for comprehensive evaluations of weld top quality. These systems are commonly integrated with sophisticated visualization tools, which facilitate the analysis of results.

Radiographic Examination Techniques

While ultrasonic screening innovations have set a high criterion in non-destructive assessment, radiographic assessment strategies remain to play an integral function in welding inspection by providing unique insights into material stability. Radiographic screening (RT) employs making use of X-rays or gamma rays to permeate materials, producing a radiograph that aesthetically represents the internal structure of a weld. This imaging capacity is very useful for identifying subsurface issues such as porosity, additions, and splits that may not show up with surface area assessments.

The process entails putting a radiation resource on one side of the weld and a detector on the opposite side. Variants in product thickness and density influence the depletion of the rays, producing a contrasting image that specifically delineates defects. RT is especially useful for inspecting thick sections and intricate geometries where various other methods may fall short.

In spite of its efficiency, radiographic assessment needs to be conducted with strict adherence to safety and security methods as a result of the harmful nature of ionizing radiation. The interpretation of radiographs calls for skilled workers, as the top quality of the evaluation straight influences the dependability of the evaluation. Subsequently, continuous improvements in electronic radiography are boosting photo clarity and interpretation effectiveness, strengthening RT's critical function in making sure weld high quality.

Laser Scanning Developments

Welcoming laser scanning innovation in welding evaluation has revolutionized the assessment of weld top quality and integrity. Unlike standard inspection methods, laser scanning offers quick data procurement, substantially enhancing the efficiency and accuracy of weld assessments.

Laser scanning advances have resulted in considerable renovations in characterizing and spotting surface defects such as porosity, lack of combination, and damages. The high-resolution information allows assessors to do extensive evaluations, guaranteeing that welds satisfy stringent sector criteria. In addition, this method sustains the growth of electronic documents, helping with long-term top quality guarantee and traceability.

In addition, laser scanning technology integrates seamlessly with software services designed for automated defect detection and assessment. The resultant information can be conveniently shared and examined, advertising collaborative decision-making processes. As industries proceed to demand greater requirements for weld top quality, laser scanning remains at the leading edge, using unrivaled accuracy and effectiveness in welding examination.

Automated Evaluation Equipments

Automated assessment systems provide the advantage of consistency, removing human mistake and subjectivity from the assessment process. They are made to operate in different atmospheres, from manufacturing floors to remote area websites, making certain comprehensive protection. Welding Inspection Madison. These systems can be set to stick to details welding requirements and criteria, providing in-depth reports and paperwork for quality control objectives

Furthermore, the integration of cloud-based platforms assists in the storage space and analysis of vast quantities of assessment information. This allows fad evaluation and predictive upkeep, allowing suppliers to resolve possible issues before they escalate. The fostering of computerized examination systems is a critical step towards improving the integrity and effectiveness of welding processes in industrial applications.

Enhancing Security and Effectiveness

A considerable facet of boosting security and effectiveness in welding inspection hinges on the integration of cutting-edge modern technologies that streamline procedures and mitigate dangers. The adoption of innovative non-destructive testing (NDT) methods, such as ultrasonic screening, phased range ultrasonic testing (PAUT), and radiographic testing, plays a crucial blog here role in guaranteeing structural integrity without endangering the safety and security of the workers entailed. These strategies enable detailed inspections with minimal downtime, reducing possible threats related to traditional approaches.

Furthermore, the implementation of real-time information analytics and device knowing formulas has actually transformed the means examination data is translated. By using predictive analytics, potential problems can be determined prior to they manifest right into vital failings, ensuring prompt treatments and maintenance. This positive approach substantially improves functional performance and safety and security in welding procedures.

Furthermore, remote examination modern technologies, including drones and robotic spiders outfitted with high-resolution cams, enable assessors to evaluate hard-to-reach areas without revealing them to unsafe conditions. This not just improves examination accuracy yet also minimizes human look at here threat. By leveraging these sophisticated devices and methods, industries can attain higher safety and security criteria and functional performance, ultimately leading to more sustainable and reliable welding assessment methods.

Conclusion

The integration of innovative devices and approaches in welding examination substantially enhances defect detection and ensures architectural stability. These improvements not only increase assessment performance however also add to improved security and top quality assurance in industrial Your Domain Name welding applications.

Ultrasonic screening innovations often represent the leading edge of innovations in welding assessment technologies.While ultrasonic testing technologies have actually set a high standard in non-destructive evaluation, radiographic evaluation techniques proceed to play an important role in welding evaluation by offering one-of-a-kind understandings into material integrity.Embracing laser scanning technology in welding examination has transformed the assessment of weld quality and honesty. As sectors continue to demand higher standards for weld high quality, laser scanning remains at the leading edge, providing unmatched precision and efficiency in welding examination.

Automated examination systems use the advantage of uniformity, removing human mistake and subjectivity from the evaluation process.

Report this page